Industrial process automation = automation + mechanics + robotics

Quick contact: + 48 61 840 80 26 || How to get to...

Two-way pallet transport system. The use of a gravity drive and bi-directional rollers allowed for the reduction of electrical wiring.

The so-called Lockbolt assembly station for the subassembly of the car seat - cushion. An automated station equipped with pneumatic riveting machines and pneumatic drives. Full process control with reporting to the traceability system.

Pallet transport system. Implementation of a system solution by Bosch Rexroth in the field of conveyor technology. Transport was an integral part of the complete production line for automotive components.

STD station for screwing together car seat components. Station with a rotary circulation of pallets. The processes of pneumatic riveting and twisting have been implemented. Station with full process control and reporting to the traceability system.

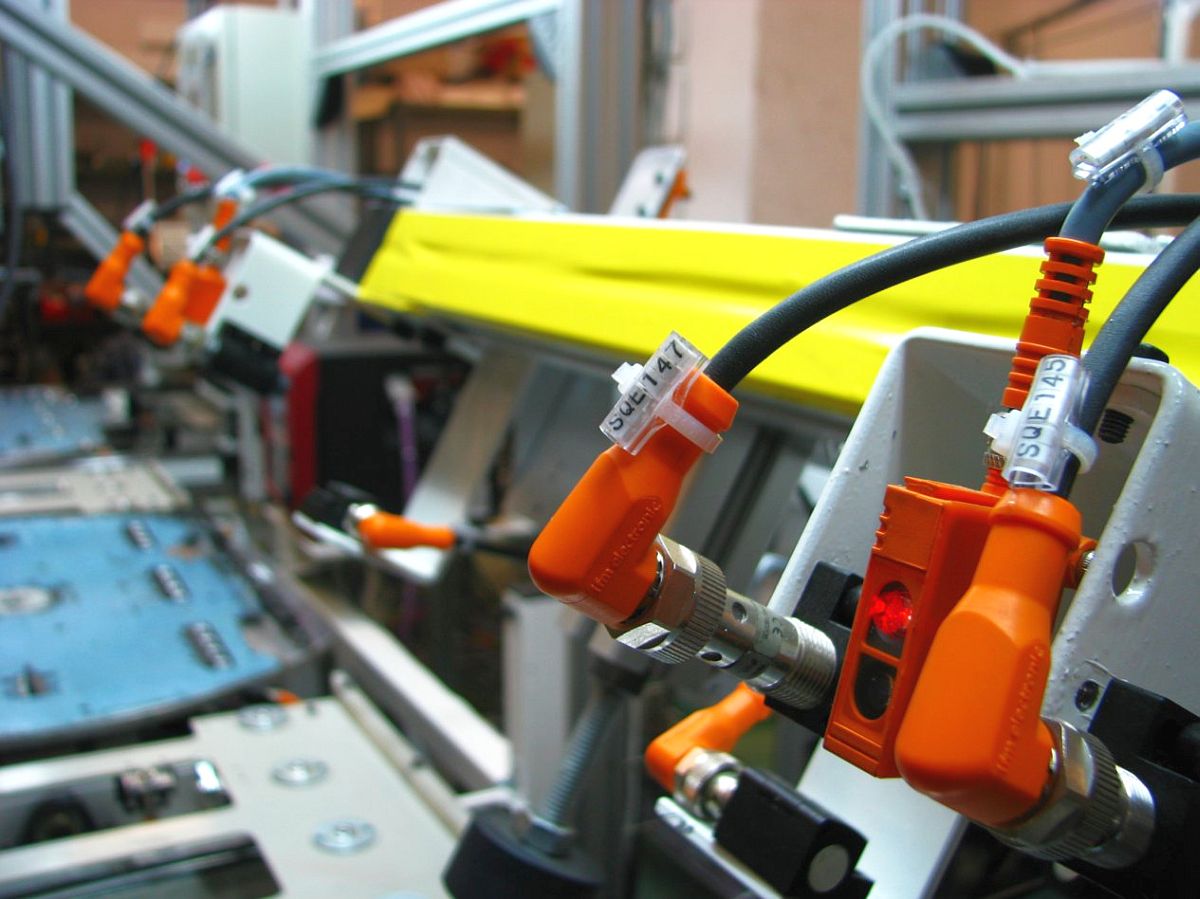

Assembly component detection system. Gearbox subassembly line. The stand is equipped with a number of sensors to control individual features of the product's equipment. Any inconsistencies are automatically archived in the machine's memory and, if necessary, can be exported to the superior system.

Car window lifter stock riveting station. Riveting is performed using a Tox pneumohydraulic actuator. The process is confirmed by the pressing pressure and the distance traveled during riveting, which gives us the certainty that the correct process is performed.

The mechanism of drive and tension compensation of the labeller. An industrial labeller requires a fast drive and a quick-response compensation system. Both of these systems have been implemented thanks to the use of the best mechanical solutions.

Pantograph for checking the torsion of threaded joints. Thanks to the position control of the screwdriver, it is possible to assign the twist values to a given screw. Control of the position of the screwdriver head by means of encoders on the pantograph. System maintenance free. High precision and speed of reading with the simultaneous possible load on the arm with a large weight of the screwdriver. The device has an adjustable balance for the key, which allowed the operator to work comfortably.

Car window guide riveting station. Application of pneumohydraulic drives. Device with full process control. The system of automatic lubrication of components was used before assembly by Dopag. By replacing the tooling, the device can handle several projects.

Installation of drip chambers. High-speed rotary table vending machine for the medical industry. Advanced mechanical solutions, advanced vision systems, a set of vibrating feeders with distributors of parts from the feeders. Advanced control system and high manufacturing precision due to the high accuracy of the folded components.